Now, during this lesson, we will see how to drill them.

1. First of all, let’s see how to describe the subsurface characteristics, in order to plan the design of the future well and to define the phases of the drilling job.

2. Then, we’ll describe the drilling system, and how the driller can manage the drilling process safely.

During the exploration phase a well is needed to confirm the presence of oil or gas in the reservoir.

Some appraisal wells are needed for the delineation process.

Moreover, at the end of the reservoir strategy study, a reservoir model defines how to develop the field, and, more particularly, where to drill the wells and the contribution of each of them to the production plateau.

The role of the driller is to build these wells required for the field development.

A well is an expensive item. It must be carefully studied and planned before being drilled. The well preparation phase involves coordinated work between geoscience engineers and drilling/completion engineers.

How to design a well?

In order to set up the drilling program, the driller needs to know the location of the rig, where the well has to enter the reservoir, the trajectory of the well in the reservoir for a good connection between the well and the reservoir, and the formations to be drilled. Let’s detail the description of the subsurface.

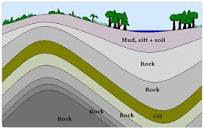

For each formation to be drilled, there are 2 characteristics that need to be known accurately:

1. the pore pressure

2. and the fracture pressure.

The pore pressure is the pressure of the fluid within the grains of the rock. It depends on the depth of the formation and on its nature (sandstone, shale, …).

The fracture pressure corresponds to the minimum pressure to be applied on the rock to generate a fracture.

When the formation is drilled, the well is full of a fluid: the drilling mud, which is directly in contact with the rock, and applies a pressure on it: Pmud.

The mud pressure depends on the depth. One of the roles of the mud is to maintain the interstitial fluid within the rock, in order to avoid a kick.

During the drilling process, the mud is in contact with the rock, which contains a fluid within the grains.

A fluid always flows from high pressure to a lower pressure. If the mud pressure is higher than the pore pressure, the formation fluid cannot enter the well. It remains in the formation and there is no risk of blowout.

During the drilling process, the mud is in contact with the rock, which contains a fluid within the grains.

The mud pressure has to be lower than the frac pressure, in order to avoid the rock being fractured. To conclude, keep in mind that the mud has to be designed so that the mud pressure belongs to the interval between the pore pressure and the frac pressure. This interval is called the mud window.

Both Ppore, in red, and Pfrac, in blue, can be plotted on a (pressure/depth) graph.

The mud pressure has to be in the yellow zone, which is called the mud window. For each lithology to be drilled, the mud has to be well adapted to its characteristics. The well is therefore drilled in different phases, each phase corresponding to a new mud to be used.

At the end of a phase, a casing is installed and cemented to protect the well from the formation already drilled and to finalize the well walls.

The definition of each of these phases is called the well design.

A typical well design is as follows:

1. The first tubular is the conductor pipe installed by the civil engineer before the rig

arrives on site.

2. The next phases are drilled using the rotary drilling technique.

3. The surface casing maintains the unconsolidated surface formations and protects the groundwater.

4. The intermediate casing protects the well from the formations or fluid which could prevent the drilling process from continuing.

5. The last casing is the production casing which allows the reservoir to be isolated.

6. During the last phase the well enters the reservoir.

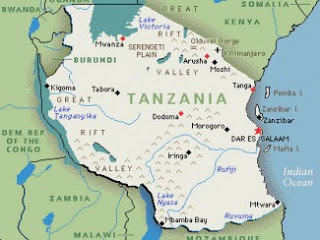

When a well is an exploration well, designing is much more difficult , due to a lack of measurements and information to describe the subsurface. The mud window is not accurately known. Such uncertainties have to be taken into consideration in the drilling process.

When a well has to be drilled in a new region, there are many uncertainties about the data, including that related to the pore and frac pressure profiles. On the contrary, when a development well is planned, it benefits from data from the surrounding wells already drilled. In this case, the pressure profiles are well known, and the uncertainties are lower.

Let’s mention that the trajectory of a well can be vertical, deviated, or horizontal. The choice of the trajectory depends on the location of the rig, the location of the target of the well when it enters the reservoir, and the trajectory of the drain in the reservoir itself. These two last data are defined and given by the reservoir engineer to the driller.

How a well is drilled in practice? Mechanically, a vertical force applied on the drilling bit (the weight on bit), together with a movement of rotation, generates down to the bit the power necessary to destroy the rock. A hook hangs up the drill string, which is composed of several tubulars screwed together, and, at the bottom, there is a drilling bit.

Both the weight on bit and the rotation per minute, which is given by the rotary table located at the rig floor, are controlled by the driller to maximize the rate of penetration of the bit.

Their optimization depends on several parameters, including the kind of rock to be drilled: the regulation of the hook height controls the part of the total weight of the drillstring applied on the bit, the rotation is often given by a rotary table located at the rig floor.

The mud circuit is combined to the mechanical part of the system.

Firstly, the pump sends the mud at high pressure through the discharge line, the stand pipe, the rotary hose and the top drive, into the pipes.

The mud flows in the drill string down to the bit and catches the small pieces of broken rock, the cuttings, to transport them up to the surface in the space between the drill string and the well walls.

At the surface, the cuttings, the sand and the silt are removed from the mud through shale shakers and other systems.

The mud can be sent to the tanks in order to be re-injected.

In order to control the well in case of blowout, a Blow Out Preventer is installed between the top of the well and the rig floor. This BOP stack is composed of an annular BOP and different rams able to close the well in case of emergency. The size of the BOP is adapted to the maximum pressure that can be encountered during the drilling process.