Countries seeking to develop newly-discovered petroleum resources are

facing a fall in global oil prices, with competition from the ‘shale

gas revolution’ in the United States, as well as renewable energy

sources.

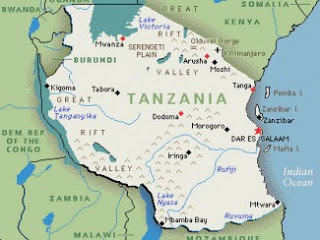

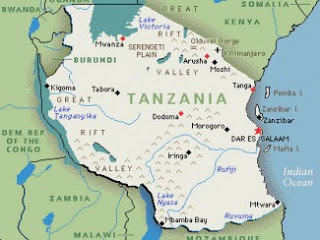

At a New Petroleum Producers Discussion Group in Tanzania, organised

by Chatham House and co-sponsored by the Commonwealth Secretariat,

authorities from more than 20 countries met this week to find solutions

to these and other shared challenges.

The four-day forum from 30 June to 2 July, at which a set of Guidelines on Good Governance for Emerging Oil and Gas Producers was

released, was attended by government ministries and national oil

companies from Belize, Guyana, Kenya, Mauritius, Mozambique, Jamaica,

Seychelles, Trinidad and Tobago, Tanzania, and Uganda, among other

nations.

“In the midst of the oil crisis there is less capital available for

investment,” commented Michael Mwanda, Chairman of the Tanzania

Petroleum Development Corporation, which hosted the meeting in Dar es

Salaam. “Some projects which were pegged on a high oil price are now

becoming uneconomic and difficult to operate.

“We need to learn from each other and share experiences on how to

reduce costs, operate efficiently and become more competitive,” Mr

Mwanda said.

Addressing the forum, Ekpen Omonbude, Natural Resources Adviser at

the Commonwealth Secretariat, remarked: “This price decline has

necessitated a critical look at strategies to manage petroleum

resources, from development programmes to responsible wealth management,

to ensure benefits for future generations.”

Dr Omonbude stressed that while the slump in the price of oil – from

over US$100 a barrel in 2014 to around US$60 today – presents immediate

challenges, these can be mitigated through the adoption of flexible

fiscal regimes, increased economic diversification, the development of

good governance regimes and revenue transparency.

“Our mission is clear – to help position our member countries to

realise the potential of their resource wealth as a driver of

sustainable development and economic prosperity,” the Commonwealth

representative said.

The

New Petroleum Producers Discussion Group was

established in 2012 to help countries think critically about policy

options available either during the first steps of exploration and

development or when restructuring governance arrangements. Options

include setting up regulatory institutions and drafting regulations and

laws that encourage investment, while balancing the needs of society and

environmental protections.

This week marked the first time the discussion group has met outside

London and included a final-day national seminar for representatives of

Tanzania’s oil and gas sector. Co-sponsors of the initiative include the

Natural Resource Governance Institute and the Africa Governance

Initiative.

Dr Valérie Marcel, Associate Fellow at Chatham House, principal

author of the guidelines, said: “The emergence of shale oil and new

renewable technologies offer opportunities and challenges. How the

emerging producer is affected and will respond is what we have been

debating. One of the main issues is how to adjust to a low price

environment, asking what impact is this going to have on licensing terms

and the ambitions of national oil companies.”

She added: “Emerging producers are thirsty to learn from their peers

about what has worked elsewhere and what advice to give. More

established producers want to know whether they are doing things right

and what pitfalls they should avoid. This is a really important learning

process.”

During the forum, participants exchanged experiences on how to

attract investment while preserving long-term national interests,

managing expenditure plans as well as ways to guard against abuses and

fraud in contracts and licensing. Training sessions focused on involving

local suppliers in supply chains, the design of fiscal systems and new

information tools.

Eddy Belle, Chief Executive of PetroSeychelles, the national oil

company of Seychelles, said: “[Petroleum] is a very dynamic business –

there is new technology coming in and new ways of doing things. What

Chatham House is doing with the help of the Commonwealth Secretariat is

getting people together so you have the chance to learn from the

mistakes as well as the successes of others.”

Bashir Hangi, Communications Officer for Uganda’s Petroleum

Exploration and Production Department, commented: “Such a forum helps us

a lot as emerging producers. We peer review ourselves, and our people

go home with a lot of advice. One piece of advice I would share is that

you cannot ignore your stakeholders – civil society, academia and

communities where there are operations. They should not be taken for

granted; they should be brought on board and be involved in the

management of the resource.”

Anthony Paul, Managing Director of the Association of Caribbean

Energy Specialists, said: “Oil and gas resources give opportunities to

deepen industrialisaton, providing power and access to better lighting,

heating and cooking facilities as well as petrochemicals and

fertilisers. There are also benefits from developing the services

industry. What strikes me most is that all countries want the same

thing: they want the resource to benefit their citizens.”